Deslagging Agent Steelmaking Flux Bulk Cosolvent Carbon Steel Flux A B C D E

Introduction:

The flux removes impurities and forms slag. The slag is separated from the steel and poured into the furnace as a liquid. It also reduces refractory wear and tires and provides foam for long bow operation. If you use lime, unless a special oven is injected you need a finer product.

Used:

Calcium aluminate (formerly known as polished aluminum and calcium) is mainly used to remove sulfur, oxygen and other impurities from molten steel in LF furnaces and furnaces to refine and convert ladle, as well as harmful elemental content and reduce impurities in steel. . Suitable for ordinary carbon steel, high carbon steel, high and low steel.

Ingredient:

Al₂O₃ : White solid, almost insoluble in water. Odorless. Tasteless. This is very difficult. It is easy to absorb moisture without dissolving (burning does not absorb moisture). The oscillating oxide soluble in the inorganic acid and alkali solution is almost soluble in water and a non-polar organic solvent. Relative density (d204) 4.0. The melting point is about 2000 ° C.

CaO: white or gray block or granules. Sensitive to moisture. It is easy to absorb carbon dioxide and water from the air. It is easily soluble in water, forms calcium hydroxide, produces a lot of heat, is soluble in acid, glycerin and sucrose, and is almost insoluble in ethanol. The relative density is 3.32 to 3.35. The temperature was 2572 °C. The boiling point is 2850 ° C. The refractive index is 1.838. erosion.

Specification:

| Grade |

Chemical Composition(%) |

| CaO |

Al ₂ O ₃ |

SiO ₂ |

Fe ₂O ₃ |

MgO |

P |

S |

H ₂O |

| FLUX A |

60-80 |

≤3.0 |

≤8 |

≤2 |

5-10 |

- |

- |

≤1.0 |

| FLUX B |

45-55 |

35-40 |

4-6 |

≤2 |

6-8 |

- |

- |

≤1.0 |

| FLUX C |

45-55 |

40-50 |

≤2 |

≤2 |

- |

- |

- |

≤1.0 |

| FLUX D |

50-60 |

30-38 |

≤3 |

≤2 |

≤1 |

≤0.02 |

≤0.1 |

≤1.0 |

| Size: 3-10mm, 10-50mm |

| Other chemical composition and size can be supplied upon request. |

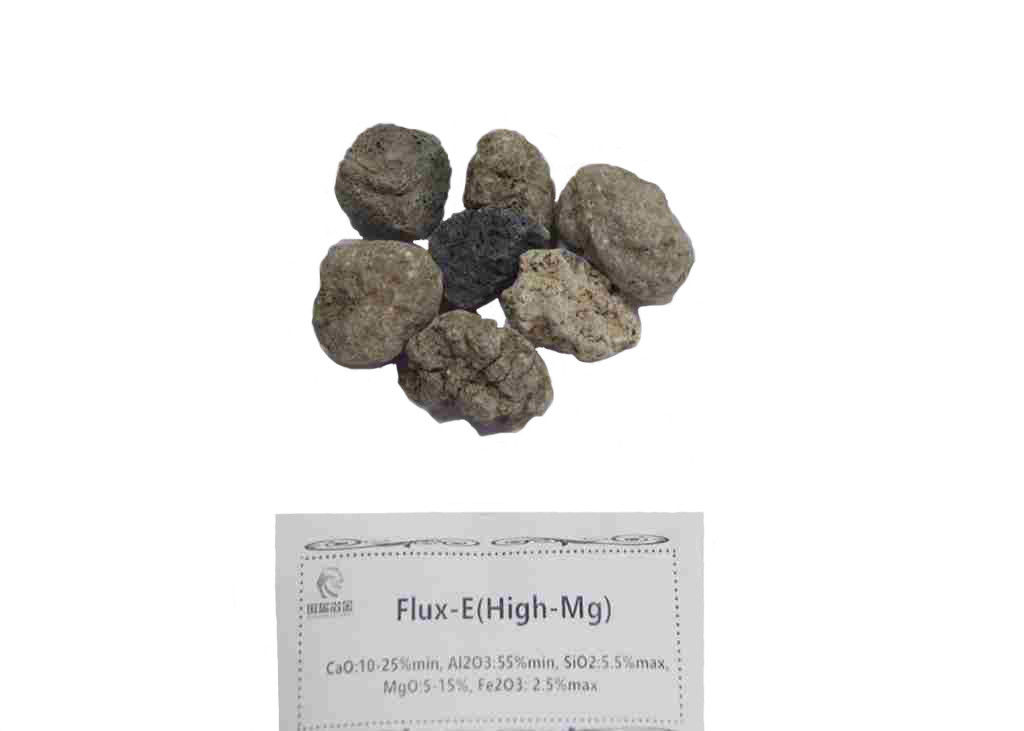

Graphic:

F & Q:

1. What is our MOQ?

Basically, our MOQ is 20 tons. There is no specific limit to order, we can give the best offer according to your situation.

2. Do you provide samples?

Yes, we do. Samples are always available and they can be sent to you directly.

3. How long does the delivery time take?

Our normal delivery time takes about 3 weeks once the contract singed, but it also depends on the quantity of the order.

4. Can we visit your plant?

Of course, we will be always looking for you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!